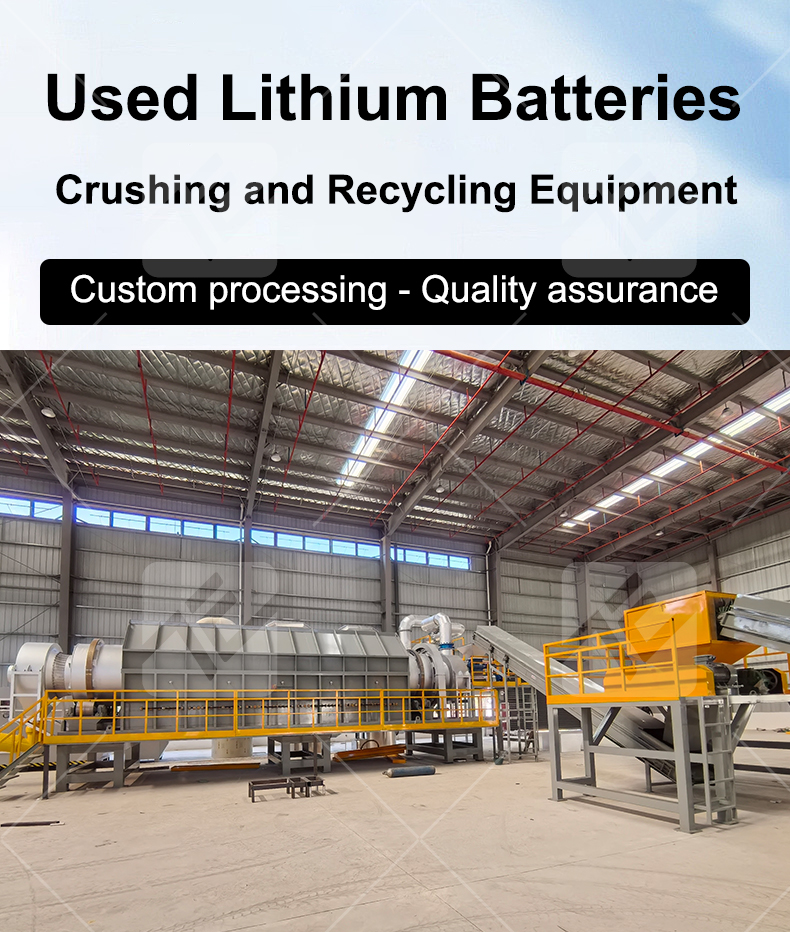

Product Introduce

The lithium battery recycling production line is based on the structural characteristics of the negative electrode of the lithium battery, and adopts the combined process of crushing and screening and air separation, and conducts separation and enrichment research to realize the efficient separation and recovery of the copper, aluminum and carbon powder of the negative electrode of the waste lithium battery.

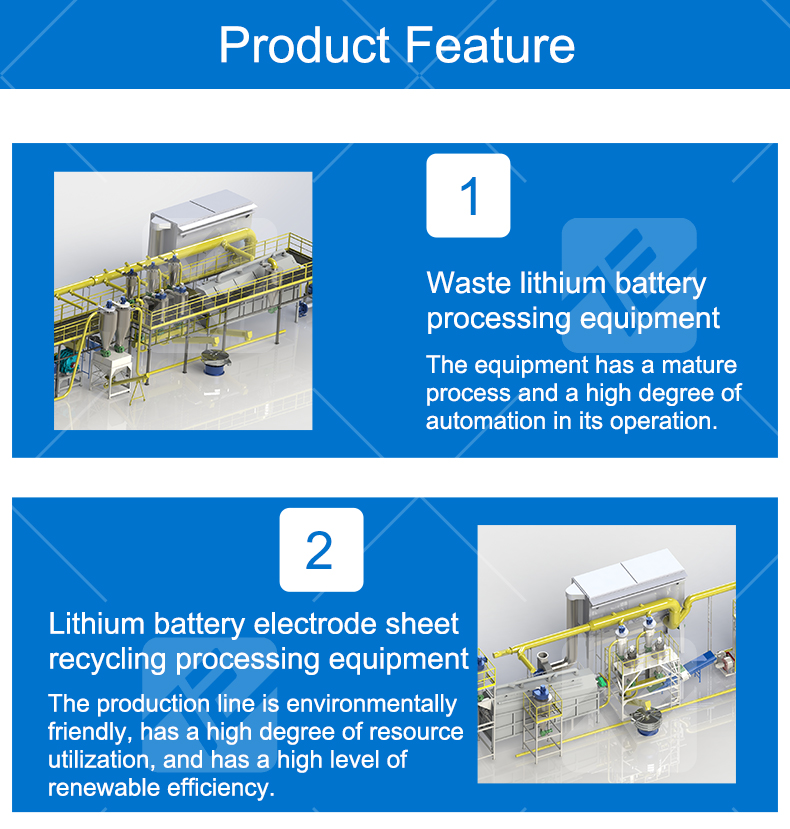

Structural Feature

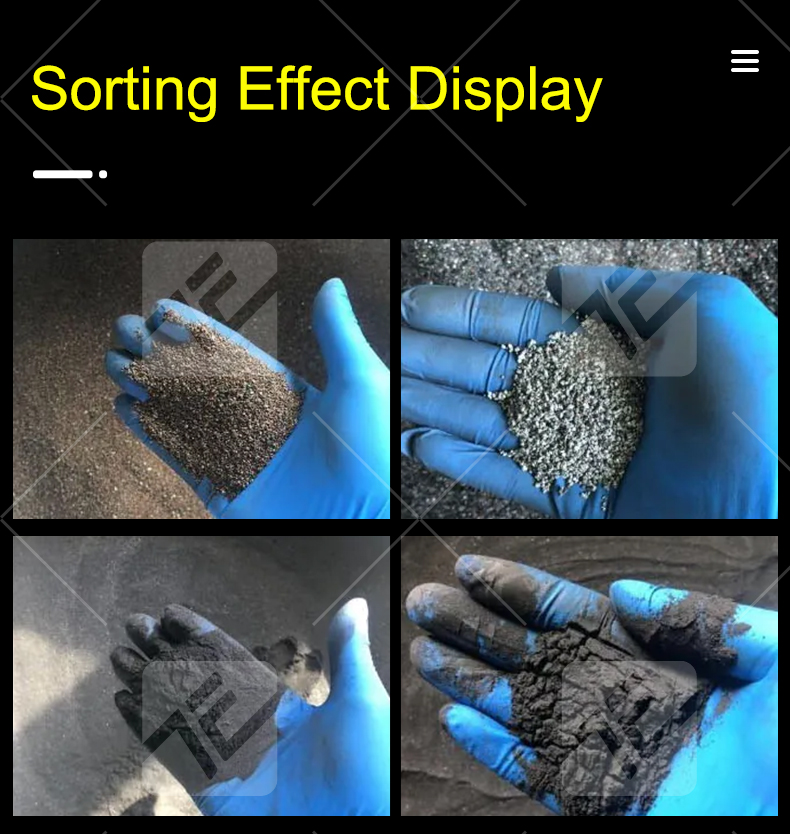

1. The resource utilization of metal copper and carbon powder in the negative electrode material of waste lithium battery can be realized through the combined process of hammer crushing, vibration screening and air separation;

2. The negative electrode material can be effectively separated from the carbon powder and the copper foil after being crushed by hammer vibration, and then the copper foil and the carbon powder can be preliminarily separated by vibration sieving based on the difference in size and shape between the particles;

3. For crushed particles with a particle size of 0.125~0.250 mm and a low copper grade, air separation can be used to achieve effective separation between copper and carbon powder. When the air velocity is 1.00 m/s, a good recovery effect can be achieved. ;

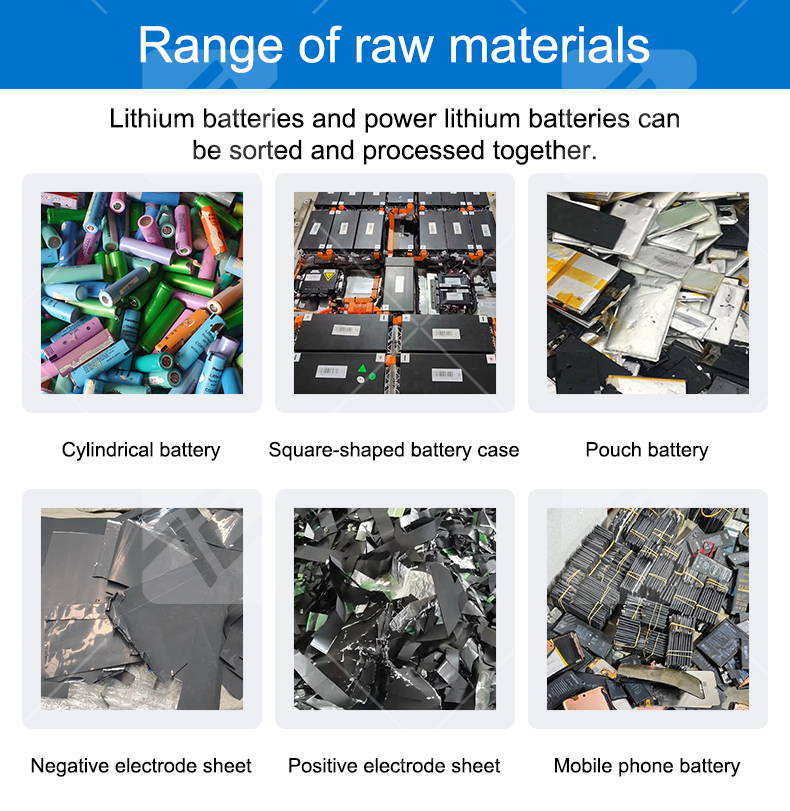

4. This equipment is mainly used for lithium-ion battery manufacturers to separate and process aluminum poise, copper poise and positive and negative electrode materials in scrap positive and negative electrode sheets for recycling purposes. The complete set of equipment operates in a negative pressure state, without dust leakage, and the separation efficiency can reach more than 90%.

Working Principle

The lithium battery is mainly composed of a shell, a positive electrode, a negative electrode, an electrolyte and a separator. The positive electrode is formed by coating lithium cobalt oxide powder on both sides of the aluminum foil current collector through PVDF that acts as a bond; It is formed on both sides of the copper foil current collector.

Battery recycling production line is configured with a combined process of hammer crushing, vibrating screening and air separation to separate and recycle the negative electrode components of waste lithium batteries.

Copyright © Henan Toeco Machlnery Co., Ltd. All Rights Reserved