Product Introduce

Eddy current separator is mainly used to recover non-ferrous metals such as copper and aluminum from industrial waste and domestic waste. It has excellent sorting effect on various non-ferrous metals, strong adaptability and reliable mechanical structure; it has the characteristics of strong repulsion (adjustable) and high sorting efficiency. The non-ferrous metal sorting machine consists of two parts: the main body of the sorting machine and the control cabinet; the main part mainly includes the selection assembly, the driving motor, the frame and the cover body. The sorting assembly becomes the core component of the equipment, which consists of a rotating drum, a material conveying system (including a material conveying belt, a conveying belt drive drum and a geared motor).

Structural Feature

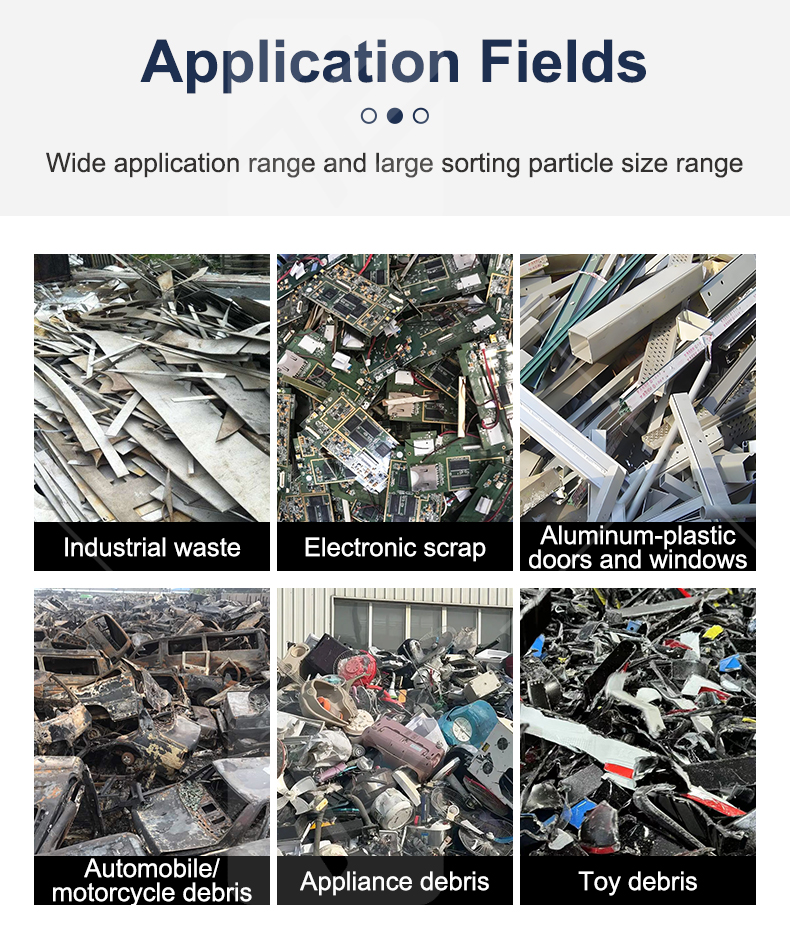

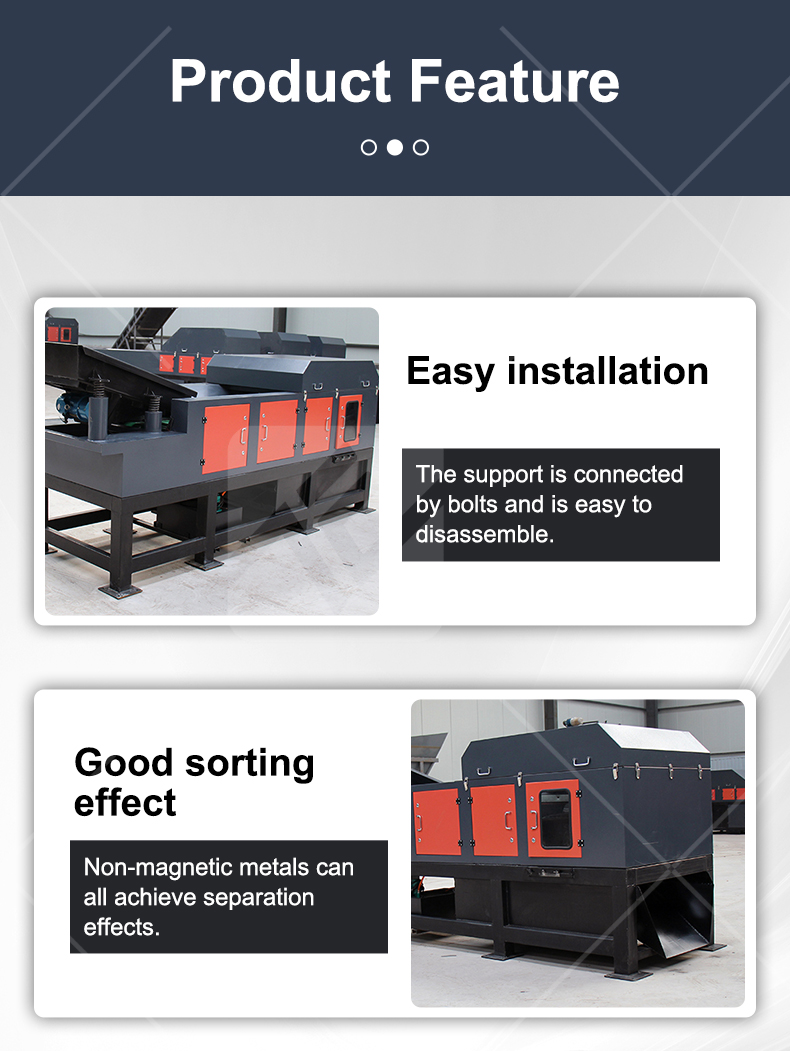

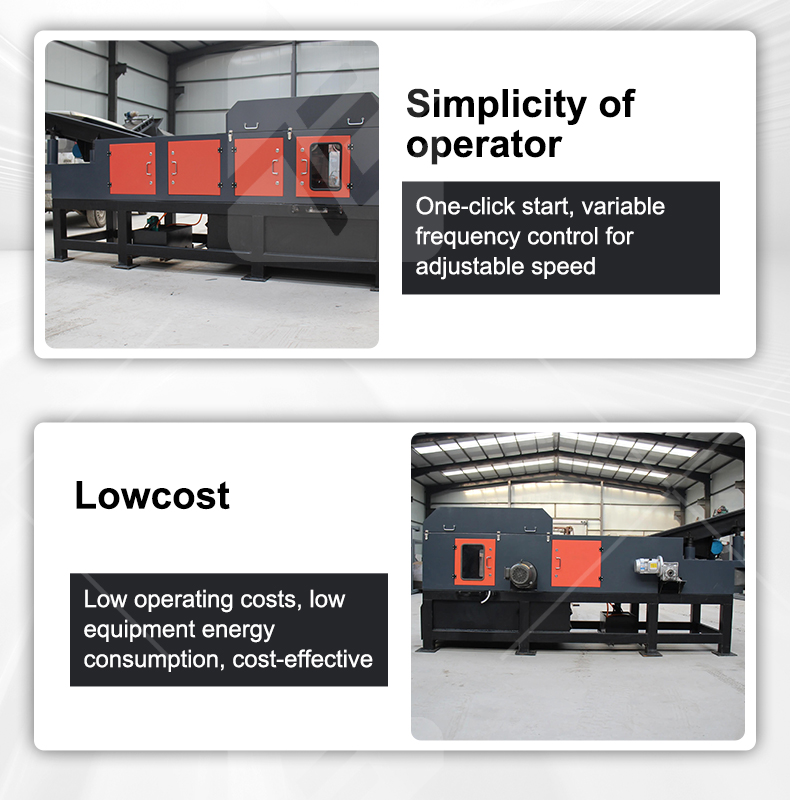

1. The separator is easy to operate and convenient to install, and can be effectively connected with the new or existing production lines.

2. Suitable for a variety of non-ferrous metal sorting, it has good effect, great adaptability and reliable mechanical structure. It has the characteristics of strong repulsion force (adjustable) and high sorting efficiency.

3. It can sort the materials of different particles according to the different turning direction of magnetic roller.

4. Themore even material shape and size, the better sorting effect.

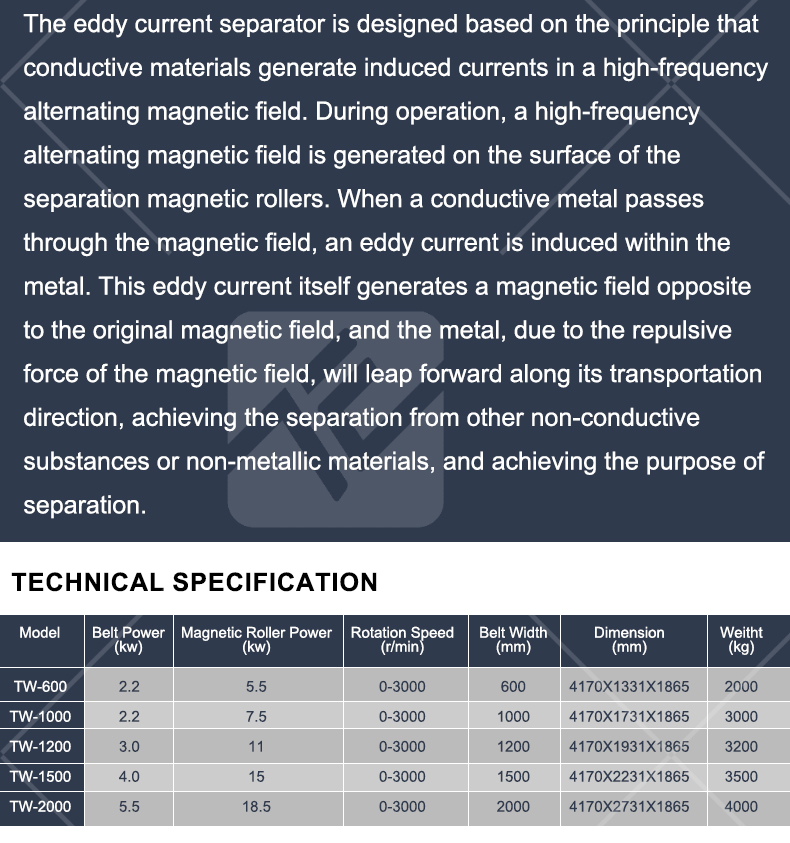

Working Principle

When the eddy current separator is working, a high-frequency alternating strong magnetic field is generated on the surface of the magnetic separation roller. When the conductive non-ferrous metal passes through the magnetic field, an eddy current will be induced in the non-ferrous metal, and the eddy current itself will Generate a magnetic field opposite to the original magnetic field, and non-ferrous metals (such as copper, aluminum, etc.) will leap forward along their conveying direction due to the repulsive force of the magnetic field to achieve separation from other non-metallic substances and achieve the purpose of sorting ; The main distinguishing criterion is the ratio of material conductivity and density, and materials with a high ratio are easier to separate than those with a low ratio.

Technical Specification

| Model | Belt Power (kw) | Magnetic Roller Power (kw) | Rotation Speed (r/min) | Belt Width (mm) | Dimension (mm) | Weight (Kg) |

TW-600 | 2.2 | 5.5 | 0-3000 | 600 | 4170x1331x1865 | 2000 |

TW-1000 | 2.2 | 7.5 | 0-3000 | 1000 | 4170x1731x1865 | 3000 |

TW-1200 | 3.0 | 11 | 0-3000 | 1200 | 4170x1931x1865 | 3200 |

TW-1500 | 4.0 | 15 | 0-3000 | 1500 | 4170x2231x1865 | 3500 |

TW-2000 | 5.5 | 18.5 | 0-3000 | 2000 | 4170x2731x1865 | 4000 |

Copyright © Henan Toeco Machlnery Co., Ltd. All Rights Reserved