At present, the waste battery recycling industry has a rapid development opportunity. Cobalt, lithium, copper and plastic in waste lithium batteries are all

valuable resources with high recycling value. Therefore, scientific and effective treatment and disposal of waste lithium batteries not only has good

environmental benefits, but also has good economic benefits. Lithium batteries are mainly composed of shell, positive electrode, negative electrode, electrolyte

and diaphragm. The positive electrode is formed by coating lithium cobalt oxide powder on both sides of the aluminum foil current collector through PVDF,

which plays a bonding role; the negative electrode structure is similar to the positive electrode, and is composed of carbon powder bonded to both sides of the

copper foil current collector. Effective separation of the negative electrode components of waste lithium batteries has a driving effect on the corresponding

environmental impact in order to maximize the resource utilization of waste lithium batteries. Commonly used waste lithium battery resource methods include

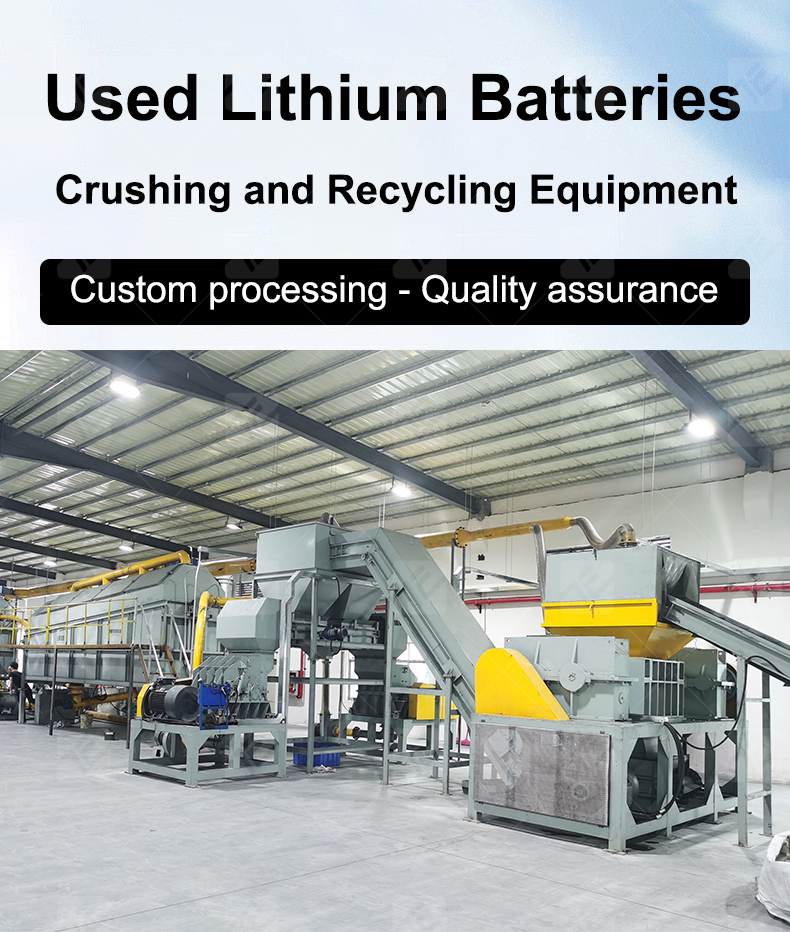

hydrometallurgy, pyrometallurgy and mechanical and physical methods. Compared with hydrometallurgy and pyrometallurgy, mechanical and physical methods do not require the use of chemical reagents and have lower energy consumption. It is an environmentally friendly and efficient method. Haozhe Environmental

Protection takes into account the positive and negative electrode structures of lithium batteries and the material properties of their constituent materials, copper

and carbon powder, and uses a combination of hammer vibration crushing, vibration screening and air flow sorting to separate and recycle the negative electrode

constituent materials of waste lithium batteries.

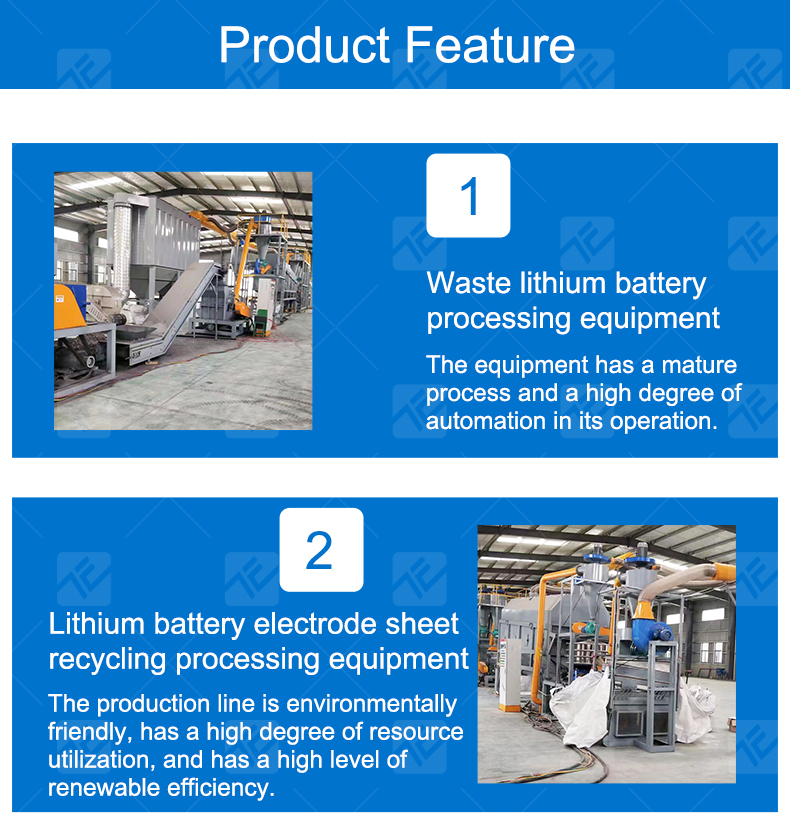

Features of lithium battery crushing, sorting and recycling equipment:

1. The combined process of hammer vibration crushing, vibration screening and airflow sorting can realize the resource utilization of metal copper and carbon

powder in the negative electrode materials of waste lithium batteries;

2. The negative electrode materials can be effectively separated from each other by hammer vibration crushing, and then the copper foil and carbon powder can

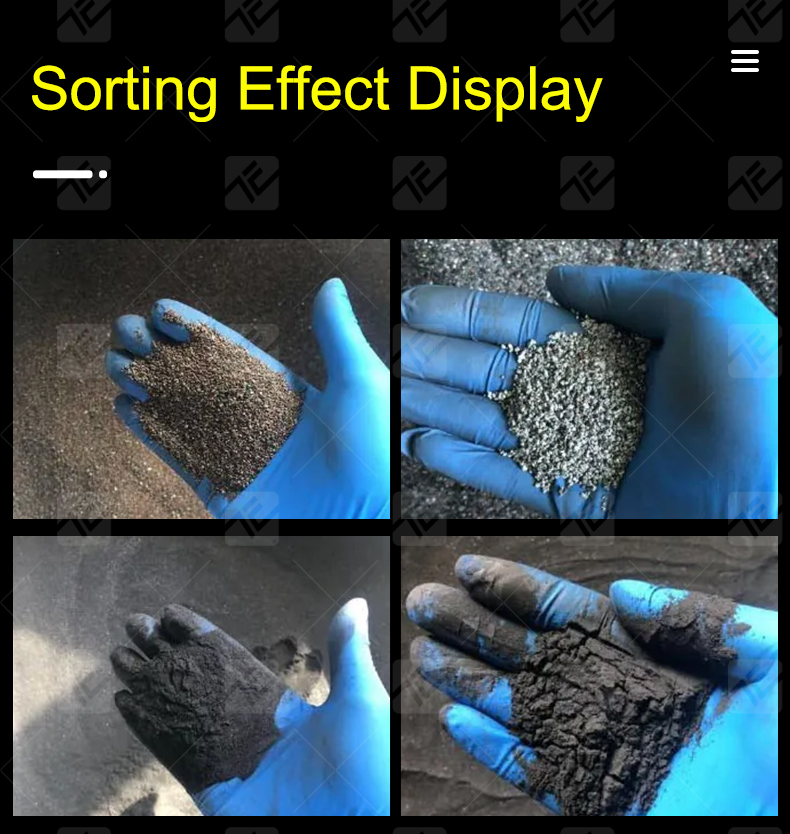

be initially separated by vibration screening based on the size and shape differences between particles. The results of hammer vibration stripping and screening

separation show that copper and carbon powder are enriched in the particle size range greater than 0.250 mm and less than 0.125 mm, respectively, with grades

as high as 92.4% and 96.6%, respectively, and can be directly sent to downstream enterprises for recycling;

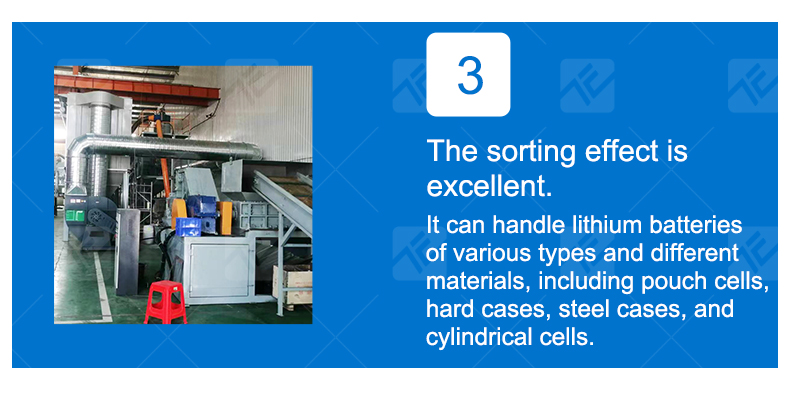

3. For broken particles with a particle size of 0.125~0.250 mm and a low copper grade, airflow sorting can be used to achieve effective separation between copper

and carbon powder. When the airflow velocity is 1.00 m/s, a good recovery effect can be achieved, and the recovery rate of metallic copper can reach 92.3%, and

the grade can reach 84.4%;

4. The equipment is mainly used in lithium-ion battery manufacturers to separate aluminum foil, copper foil and positive and negative electrode materials in

scrapped positive and negative plates for recycling. The complete set of equipment operates in a negative pressure state, without dust discharge, and the

separation efficiency can reach more than 98%.

Processing capacity: 500kg-1000kg/h

Application scope: mobile phone lithium battery, power lithium battery, positive electrode, negative electrode

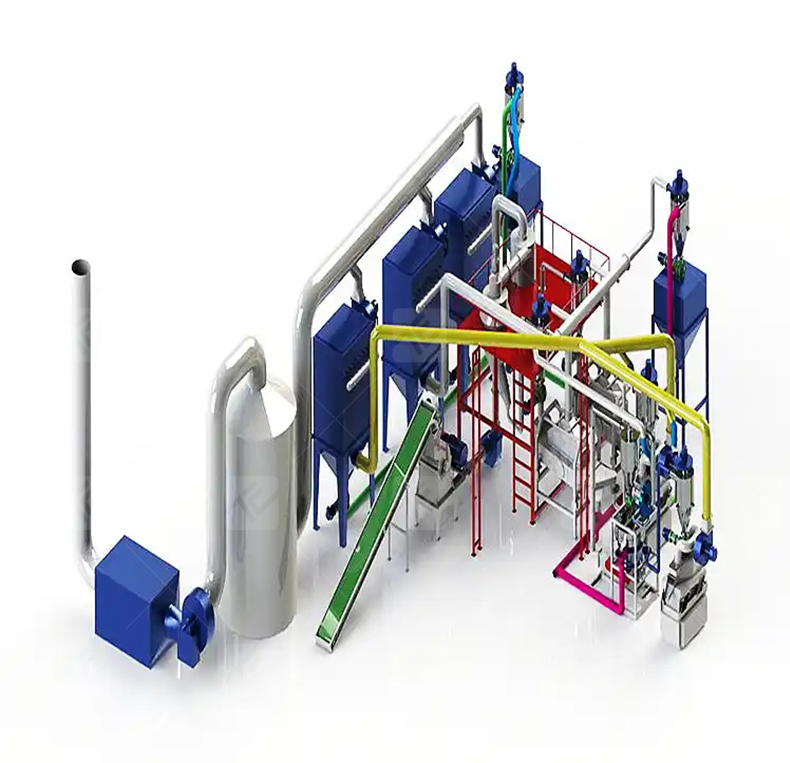

Components: crushing, wind sorting, specific gravity sorting and other equipment

Working principle of lithium battery electrode processing equipment:

Lithium battery crushing, sorting and recycling equipment structure and its constituent materials copper and carbon powder material characteristics, using

hammer vibration crushing, vibration screening and airflow sorting combined process to separate and recycle the negative electrode constituent materials of

waste lithium batteries.

Copyright © Henan Toeco Machlnery Co., Ltd. All Rights Reserved